Var B

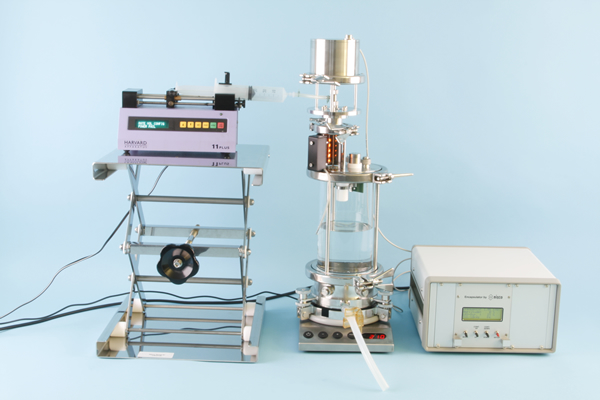

Electromagnetically driven single nozzle contained complete unit

Legend:

1 Autoclavable working vessel 2 Bypass system 3 Hardening solution / level switches 4 Bottom with 2 injection ports 5 Leveling device 6 Laboratory agitator 7A Peristaltic pump for feed 7B Peristaltic pump for retracting |

8 Syringe pump 9 Sight glass with stroboscopic light 10 Vibrator 11 Control cabinet 12 Base frame made of stainless steel 13 Flask for hardening solution, feed 14 Flask for hardening solution, retract |

in Var B included: 1,2,3,4,5,6,8,9,10,11,12

Short description

This is an electromagnetic driven sterile single nozzle unit based on the laminar-jet-breakup.

The unit with its sophisticated multipurpose design and the flexible modular expandability has been tailored to the process developer’s requirements. The modular approach in the design allows to change the unit repeatedly according to the changing requirements and to combine components delivered by us with equipment and devices already available in your laboratory.

Applications

For a large number of applications (e.g. enzyme/drug immobilization, cell encapsulation, cosmetic applications and many more) microencapsulation opens new technological possibilities.

Principle

The unit has a single vibrating nozzle (frequency and amplitude can be adjusted digitally). A syringe pump produces a steady pulsation-free flow through the vibrating nozzle. The generated drops can be observed by means of an LED-stroboscopic light as a stationary chain of drops. The stroboscopic light is automatically synchronized with the adjusted vibration frequency. Monodisperse beads of the size between 0.2 and 1.5mm can be generated. The deviations between the applications mainly depend on the viscosity and the surface tension the matrix. You can roughly estimate that the smallest achievable drop diameter is 1.5 to 2 times larger than the used nozzle diameter. The average productivity per nozzle is 400ml per hour whereas it can significantly differ in function of the nozzle diameter and the jet speed. The unit can be sterilized in an autoclave. The system is designed for a typical size of 280ml.

Control cabinet

Rack with display, four lines x 16 characters, programmable micro controller for vibration control and stroboscopic light.

Power supply between 110 V and 240 Volt, automatic adjusting.

![]() Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please note: You need Acrobat reader to display the following PDF - Files.

| Download Datasheet as PDF file (105KB) | |

| Download Picture: VAR B as PDF file (94KB) |