Sterile Autoclavable Container for Nisco Encapsulation unit VAR V1

Sterile container is designed for encapsulation with max. three nozzles at the same time. It is the ideal tool if you have to produce beads on high level pharmaceutical or medical standard. It is delivered with the required material certificates to ease the validation of your process.

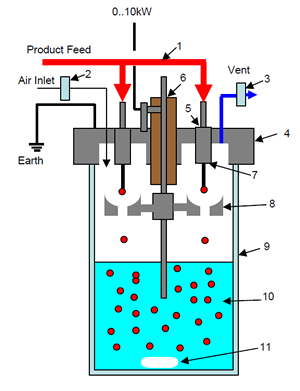

Schematic drawing :

Legend:

| 1 | Product feed to max. 3 nozzles two blinds are supplied if you want to work with one nozzle only. |

7 | Nozzle standard or special nozzles as per Nisco’s Standard |

| 2 | Air inlet to decrease humidity (to prevent short circuit) with 0.2μm filter |

8 | Electrode to compensate the increasing surface of the hardening solution. |

| 3 | Vent to decrease humidity (to prevent short circuit) with 0.2μm filter |

9 | Autoclavable Glass vessel (process is visible from outside) |

| 4 | Clamp cover on earth | 10 | Hardening solution with the beads |

| 5 | Hose connection for nozzle | 11 | Agitation element for stirring |

| 6 | Electrode on high voltage with isolation |

Aeration:

When you are producing drops in a closed container with a watery solution, the humidity within the container is gradually increased, which after a while will lead to sparkling and short circuit. To overcome the problem we recommend supplying the container with dry air. The air inlet and the air outlet filter can be equipped with a standard autoclavable sterile filter 0.2μm. Two sample filters are scope of supply.

Process Information:

The Nisco electrostatic accelerator (see the schema lefts) allows the size of the beads to be

independent from the level of the hardening solution. (The hardening solution level will gradually rise by adding polymer drops.)

Material in Contact with product: |

|

| All materials are supplied with material certificates: | |

| Stainless steel parts: | 1.4435 or equivalent |

| Electrode: | titanium |

| Isolation parts: | PEEK |

| Nozzles: | 1.4435 or equivalent |

| Gaskets: | EPDM or Silicone depending on application |

| Glass cylinder: | borosilicate |

| O-Rings: | EPDM or Silicone depending on application |

| Hoses: | silicone or polypropylene |

Materials without contact to product |

|

| Stainless steel parts: | 1.4301 or equivalent |

![]() Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please note: You need Acrobat reader to display the following PDF - Files.

| Download PDF-File Sterile autoclave container |